Water-based printing uses eco-friendly inks for bags and luggage, delivering soft, breathable, and durable prints on light-colored fabrics—ideal for canvas bags and totes

Water-Based Screen Printing Machine for Bags and Luggage – Efficient and Eco-Friendly Printing for Cotton and Polyester Fabrics

Category: Fabric Processing Technique

Tag: Craftsmanship Display

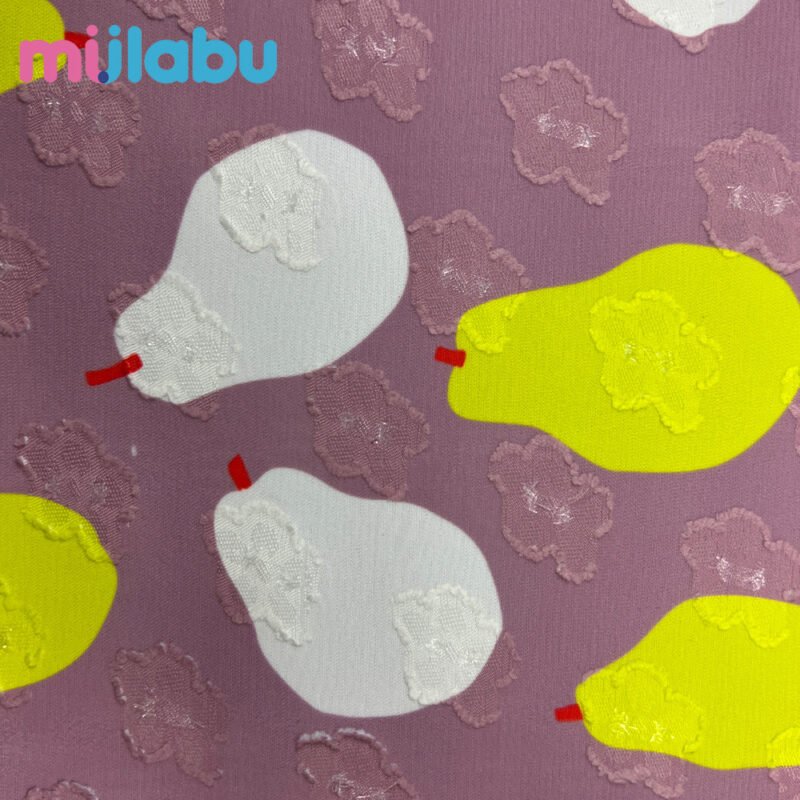

Water-based screen printing is a technique that uses water-based inks to print designs onto textiles, commonly used in the bags and luggage industry for items such as canvas bags, shopping totes, and backpacks. This process involves transferring water-based ink through a mesh screen onto the fabric, allowing the ink to penetrate the fibers. As a result, the printed area remains soft, breathable, and retains the original texture of the material. The main advantages of water-based printing are its lightweight and soft finish, excellent breathability, and high color fastness, ensuring that designs do not easily fade or peel. Compared to plastisol (rubber) printing, water-based printing is more cost-effective, suitable for large-scale production, and delivers a natural look and feel. Typical applications include logos, patterns, and promotional graphics on light-colored cotton and polyester bags, totes, and apparel. Water-based printing is also eco-friendly and odorless, making it an ideal choice for manufacturers seeking both quality and environmental responsibility in the bags and luggage sector

RELATED PRODUCTS

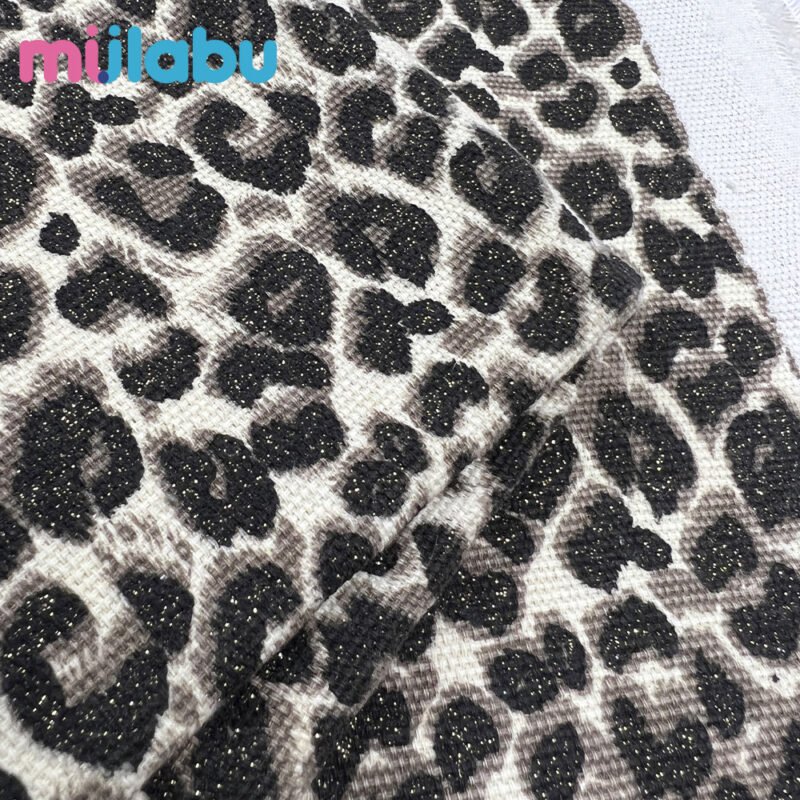

Digital Printing for Bags and Handbags – Efficient, Eco-Friendly Printing Process for Custom Designs and Mass Production

Digital printing uses high-precision inkjet technology to print vibrant and detailed patterns directly onto materials for bags and handbags. This process requires no plate making, is flexible and efficient, and is environmentally friendly. It is ideal for small-batch customization and personalized designs, and is widely used in the bags, handbags, and footwear industries