DTG digital printing is an efficient, eco-friendly textile printing technology ideal for bags and handbags. It supports personalized customization, vibrant colors, and detailed patterns with no minimum order, helping brands quickly respond to market trends and enhance product value

Direct-to-Garment Digital Printing for Bags & Handbags | High-Efficiency Custom Printing Solutions for Bag Manufacturers

Category: Fabric Processing Technique

Tag: Craftsmanship Display

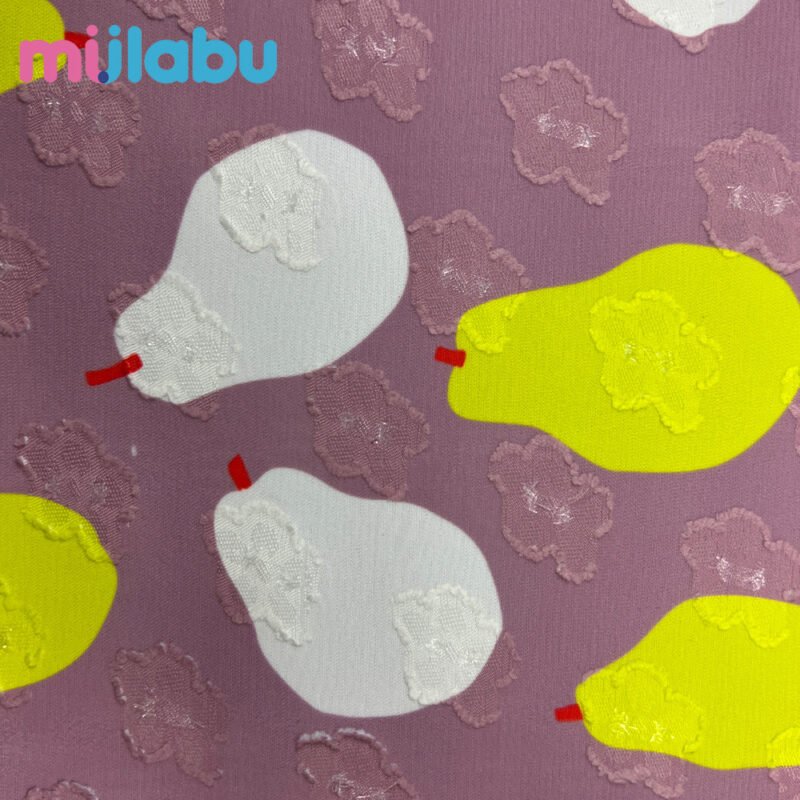

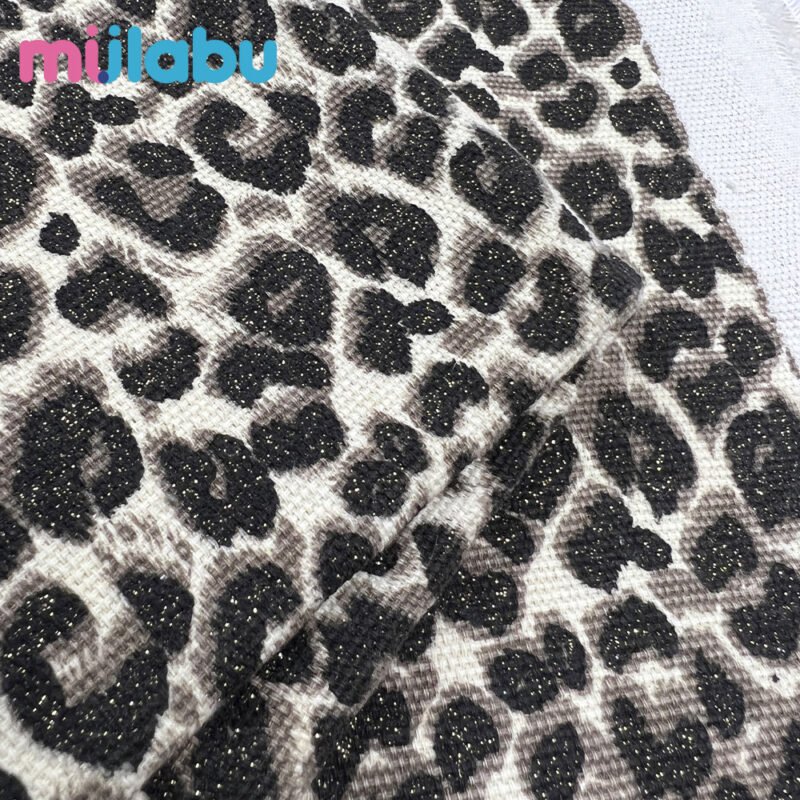

Direct-to-garment (DTG) digital printing is an advanced technique that uses digital printers to spray designs directly onto the surface of various textiles. Compared to traditional printing methods, DTG eliminates the need for plate making and complex color separation, significantly shortening production cycles and enabling true small-batch, multi-style, and rapid-response manufacturing. The process uses high-precision print heads to inject specialized inks deep into fibers, producing vibrant colors and detailed patterns that easily reproduce complex gradients and photo-quality images. DTG printing is widely applicable to cotton, linen, polyester, silk, blends, and more, making it ideal for bags, handbags, apparel, home textiles, and footwear. In the bag and handbag industry, DTG enables personalized customization, meeting the demand for diverse and fashionable patterns from both brands and consumers. Additional advantages include eco-friendliness, no minimum order quantity, flexible production, simple operation, and a soft hand-feel that preserves fabric breathability. DTG is especially suited for complex designs and small-batch orders, making it perfect for e-commerce quick-turn and small-lot production models, helping businesses rapidly respond to market changes and enhance product value

RELATED PRODUCTS

Digital Printing for Bags and Handbags – Efficient, Eco-Friendly Printing Process for Custom Designs and Mass Production

Digital printing uses high-precision inkjet technology to print vibrant and detailed patterns directly onto materials for bags and handbags. This process requires no plate making, is flexible and efficient, and is environmentally friendly. It is ideal for small-batch customization and personalized designs, and is widely used in the bags, handbags, and footwear industries